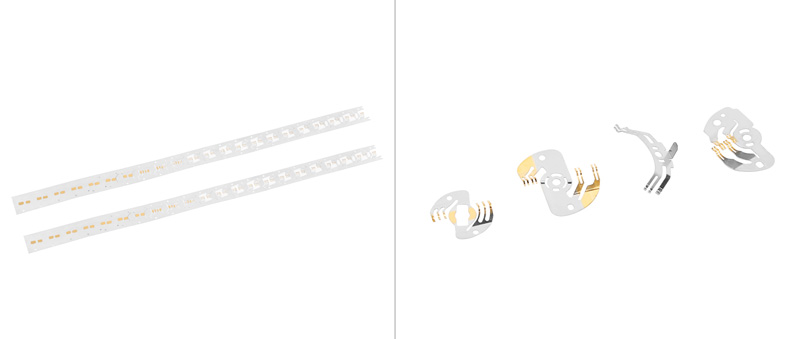

Material: SUS/CU+NI+AU

Process: Material→Electroplating NI→Electroplating AU partially→Stamping

Advantages: changing the process in the past to lower electroplating cost and deter deformation.

Application: FPC contact brush.

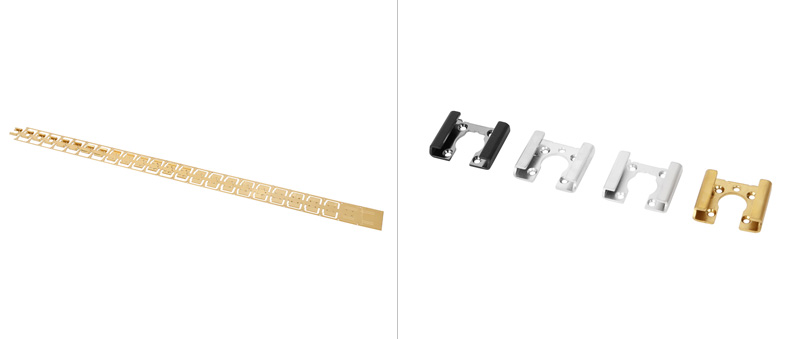

Material: Aluminum

Process: Material→Bending→Blanking

Advantages: less process (< 10 processes) with progressive stamping, highly precision mold for bending, strokes per minute 80, 50% less than the cost of die-casting.

Application: heat dissipation for mini 3C products.

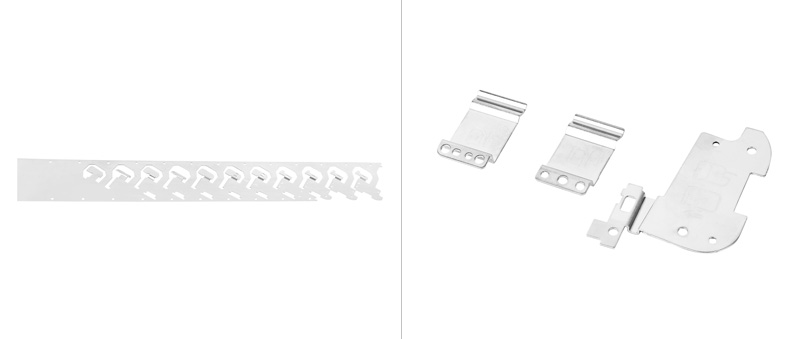

Process: Material→Bending→Blanking

Advantages: definite shape with flatness less than 0.05mm is finished after bending.

Application: cosmetic parts, flash holder (ACC SHOE).

Material: SUS

Process: Material→ Coining →Blanking

Advantages: clear shape and excellent texture by coining, reducing processing cost.

Application: cosmetic parts with texture/pattern.

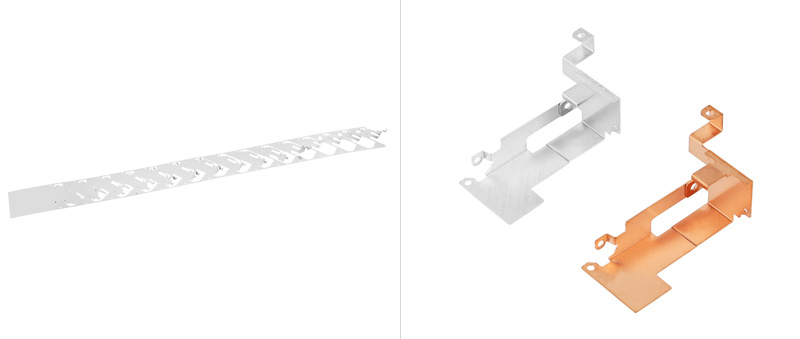

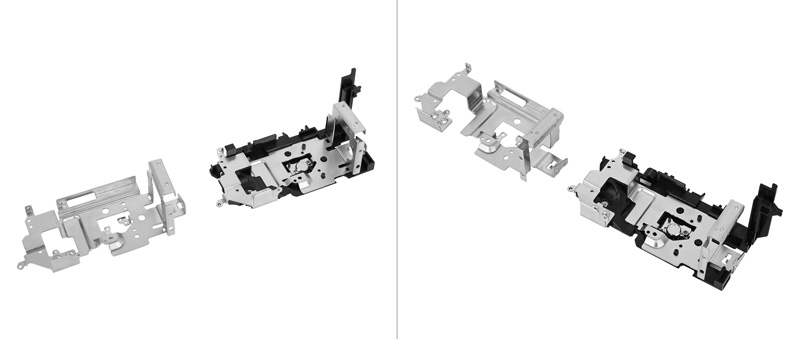

Material: Aluminum

Process: Material→Bending→Blanking

Advantages: with progressive die and precision bending technology, hole alignment through bending process many times.

Application: battery box gnd holder.

Material: SUS

Process: Material→Bending→Blanking

Advantages: bending angle of 36mm height will be less than 0.2 degree after the material is bent many times.

Application: main chassis (holder).

Process: special cosmetic painting.

Painting: metal/plastic soft touch paint, sprinkling paint, leather paint, glossy design.

Advantages: meeting customers’ special cosmetic process requirement.

Application: all cosmetic products.

Process: melting, welding, dispensing, riveting, CNC, laser marking, assembling, inspecting, packing.

Advantages: with one stop assembling including self-production and self-purchase, we can lower the cost of packing and shipment, and shorten delivery.

Application: the assembly of products, such as camera, smart phone, automobile, security control, and smart home.